Manufacturing Engineers are employed in manufacturer industries or other production facilities. Their main focus is to create high-quality items by developing effective methods, procedures, and equipment. They also look after the effects of industrial operations on the environment and strive to keep the company running smoothly while minimizing environmental effects.

Table of Contents

As a Manufacturing Engineer, your main duty is to manage, build, and run a production system. Manufacturing Engineers are also responsible for maintaining manufacturing costs down while maintaining the standard of the goods and service.

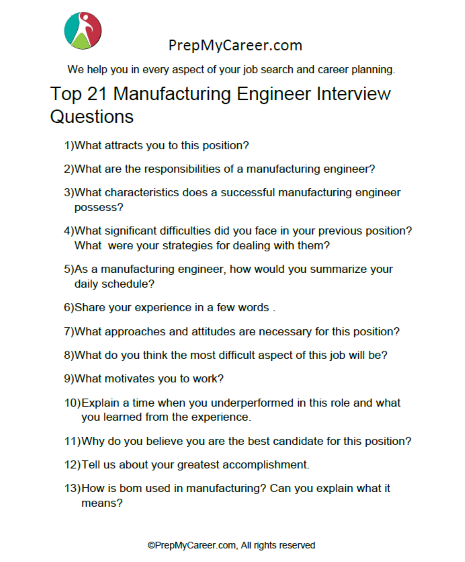

The Top 21 Interview Questions To Prepare Well

1. What attracts you to this position?

Sample Answer

I’m fascinated by this position because I want to help with production procedures. I am quite enthusiastic about this position because of my wide knowledge of industrial processes. I’ve spent a lot of time analyzing, designing, and enhancing production systems and product development. I am a critical thinker with an excellent ability to resolve issues.

2. What are the responsibilities of a Manufacturing Engineer?

Sample Answer

Manufacturing Engineers are in charge of overseeing and improving the production process. They are in charge of specifying areas for enhancement, developing new procedures and goods, working to ensure a high standard of production and product quality, trying to maintain cost-effectiveness, and adhering to regulatory guidelines, among other things.

3. What Characteristics Does a Successful Manufacturing Engineer Possess?

Sample Answer

A Manufacturing Engineer should be capable to design and manage production methods, should be a team player, possess a high degree of expert knowledge, interact efficiently, and should be organized to be successful.

4. What significant difficulties did you face in your previous position? What were your strategies for dealing with them?

Sample Answer

The most difficult part was engaging with employees who were resistant to the process modifications you implemented. I learned there was a reason why they were resistant to change. We enjoyed working together more after discovering these issues and learning how to fix them.

5. As a Manufacturing Engineer, how would you summarize your daily schedule?

Sample Answer

My typical day starts with a discussion with the production administration staff. Any work concern that has arisen within the last 24 hours is discussed. Then I stroll about the factory inspecting it while speaking with other co-workers to gain their feedback on the process we’re utilizing. I spend most of my day working on new designs to better our operations and the machinery we utilize daily. Joining management conferences, doing admin chores, interacting with suppliers, and so on are some of my other responsibilities.

6. Share your experience in a few words.

Sample Answer

Years of expertise have properly qualified me for this position. I’ve been doing the following for 5 years:

– Discovering possibilities for enhancement and assessing current production processes identifying production issues and making changes

– Arrangements for procedures, machinery, and workflow are being developed, as well as new equipment, procedures, and goods.

– Creating and executing cost-cutting and quality management system

– Assuring that production lines, processes, and commodities meet security and legal requirements.

– Documenting and report writing

7. What approaches and attitudes are necessary for this position?

Sample Answer

This work necessitates a diligent and goal-oriented individual. A manufacturing line must be operational for the entire period that it will remain in profit. If a trial fails or a piece of equipment breaks down, an engineer must act quickly to get the line moving again. They must also understand the importance of security, client timelines, and product standards.

8. What do you think the most difficult aspect of this job will be?

Sample Answer

A substantial excess of demand at any particular time can be the most difficult task. Realizing that client contentment is critical to any firm, I will do everything possible to make sure that every shipment is done on time or even ahead of schedule. Because I understand how to prioritize things, my organizational abilities will aid me in achieving my goal.

9. What motivates you to work?

Sample Answer

I am motivated by my ambition to learn and progress with a firm. I’m excited to see how far my career may take me, and being in the manufacturing field keeps me motivated.

10. Explain a time when you underperformed in this role and what you learned from the experience.

Sample Answer

A manufacturing line broke down during my initial year in this profession. As a Manufacturing Engineer, I was well aware that I was in charge of all service and quality concerns that arose throughout the production process. Even though I was unaware of fixing the issue at the moment, I kept a professional demeanor and claimed to be investigating the situation.

After a long time, I understood that I was unable to handle it and I didn’t seek assistance until late at night. When the senior engineer arrived, he found that a security monitor had collapsed, causing the line to be down. The backup was started, and production was restarted. This problem showed me the value of collaboration and teamwork.

11. Why do you believe you are the best candidate for this position?

Sample Answer

Being an analytical thinker and having a high level of technical competence, as well as good managerial and organizational skills, in addition to having a mechanical engineering degree. In my three years of practice in industrial engineering, I learned a lot about many data analysis applications and other relevant technology. I will be a valuable addition to your organization, particularly in terms of reviewing and debugging production processes and equipment.

12. Tell us about your greatest accomplishment.

Sample Answer

In my present job as a Manufacturing Engineer, we noticed an issue with workers taking out bolts on the production line. After doing a detailed analysis, I recommended moving to new power equipment. This allowed us to greatly boost the line’s efficiency while also drastically lowering the number of faults.

13. How is BOM used in manufacturing? Can you explain what it means?

Sample Answer

The Bill Of Materials, or BOM, is an acronym for a bill of materials. It includes a list of the machines that were utilized to make a product. It can also be characterized as a vendor involved in the production process. It can also relate to the materials and tools that workers utilize in a production facility.

14. What is the MES and how does it Work?

Sample Answer

The full form of MES is Manufacturing Enterprise System. It is software that tracks products and details of orders on the manufactory floor. It’s utilized to cut down on the amount of time it takes to complete an order. It captures data that is used to evaluate and improve each procedure. For instance, This software can detect delays created by workers waiting for materials or when accessing essential resources appears to be problematic.

15. What Are Your Thoughts About Six Sigma Certification?

Sample Answer

I’m a certified Six Sigma Black Belt. Six Sigma is a statistical process for identifying and eliminating faults in any production process, from transactional to item to service. It’s crucial since it provides me with the data I require to enhance operations.”

16. Are you familiar with Kanban?

Sample Answer

Yes, I utilized it in my former position. It’s a production planning system that allows companies to choose what to create, when to create it, and how much to create. It’s a useful approach to employ because it aids in the tracking of manufacturing materials and resources. It also gives the manufacturing team all of the data they need to complete an unified application.”

17. We want you to explain how you can calculate the cost of manufacturing work that is still ongoing.

Sample Answer

Basic materials, labor, manufacturing overheads, and basic admin expenses are all elements that I can track. I’ll compute the cost of the ongoing manufacturing work using each of the mentioned elements.

18. Is it possible for you to give a few examples of factory overhead?

Sample Answer

Manufacturing rent, security, utilities, admin expenses, machinery expense, depreciation, and taxation are a few examples of factory overhead.

19. In five years, where do you see yourself?

Sample Answer

This position at your organization excites me tremendously. In five years, I want to be known as someone who specializes in production technology. In the future, I hope to take on additional managerial duties in your organization, possibly directing some operations.”

20. An item has recurring quality issues that are pricey and only reaches the client on rare occasions. What are your options for resolving the state of affairs?

Sample Answer

When client concerns aren’t taken as severely as they should be, problems like this arise. Instead of trying to catch the issues on the tail end, I’d take proactive steps to eliminate them.

21. When will you be able to start working if you are hired?

Sample Answer

The new agreement requires me to give three weeks’ notification prior to leaving my current position. However, once I’ve completed that responsibility, I’ll be able to start working the very next day. I’m very excited to start working here and meet the other members of the company.

Download the list of questions in .PDF format, to practice with them later, or to use them on your interview template (For Manufacturing Engineer interview):